Historically, the power of a car’s engine was dependent on the number and size of cylinders – today, that’s a thing of the past! Electronic engine control, turbochargers or compressors are responsible for the overall performance. The turbocharger has a particularly important role—a Swiss invention dating back to 1925, the turbocharger was used to considerably increase engine power. What distinguishes this component, why is it increasingly important and what are the benefits of using electrochemical machining? —Five interesting facts about turbochargers:

- Unaltered Basic Principle

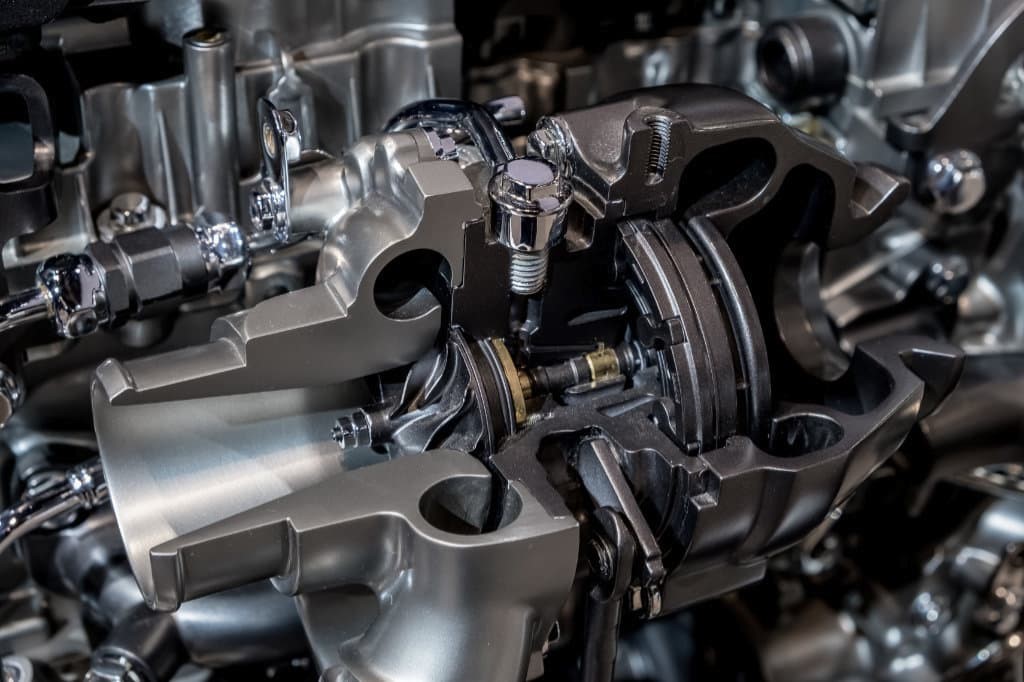

The basic principle of the nearly 100-year old invention remains the same today. The exhaust stream drives a turbine wheel, which is connected to a second wheel over a shaft. This wheel compresses the fresh air that is sucked in and presses it into the combustion chambers. The following simple calculation applies here: The more air ends up in the combustion chamber, the more oxygen molecules are connected to the hydrocarbon molecules during combustion—and this is precisely what provides more power.

- Almost 300,000 Revolutions

In the end, the purpose of the turbocharger is to achieve the optimal effect by generating the highest possible air pressure. This means that the unit achieves extremely high performance values: In modern engines, the compressor wheel completes 290,000 revolutions per minute. The component is also subjected to extremely high temperatures – which is why turbocharger models also have connections or systems to water-cool the charge air. This means that four different substances come together within this component: hot exhaust gases, cold charge air, cooling water and oil (which by the way may not become too hot).

- “Electrochemical Benefits”

Given these conditions, the production of turbochargers can definitely be classified as one of the most demanding tasks in automotive production. This applies to both the complex housing and the turbine shaft. These components are manufactured from high-performance materials that can easily withstand temperatures of up to 1,000 degrees Celsius (1,832 degree Fahrenheit) such as heat-resistant cast steels or Inconel alloys. Their machining is frequently performed within the scope of an extensive process chain from pre-milling all to way to deburring. Chip free electrochemical processes provide great benefits in this context (read more about this here). For example, they allow the turbocharger shaft to be balanced with a single repeat step. There is no thermal damage to the material and tool wear is minimal even with the hardest of materials—these are major advantages over conventional machining techniques. After all, inconel and similar materials are responsible for shorter tool lives.

- Increasingly Important

The fact that the production of turbochargers is becoming increasingly demanding has a lot to do with the major downsizing trend in the automotive industry: The displacement of many combustion engines is shrinking, while turbocharger compression ensures constant, or even increasing performance. Interestingly, downsized engines are even heavier than similar engines without a downsized design due to the additional weight of the turbocharger and intercooler. To decrease overall weight, developers are moving toward reducing the thickness of the housing wall, which puts more demand on conventional machining.

- Future Challenges

Turbocharging continues to be a key technology for the development of economical and efficient engines. However, various technological trends present new challenges. For example, systems that are part of the exhaust gases are cooled, mixed with the charge air and recirculated into the engine are more frequently being implemented. This exhaust gas recirculation (EGR) is one of the major solutions implemented to reduce diesel engine emissions. As a result, the turbocharger must press more air into the combustion chamber in order to supply it with a sufficient amount of oxygen. Many manufacturers are relying on two-stage charging, which involves two different turbochargers.